How To Clean Carbon Brushes . clean the motor regularly: Clean dust and impurities in time to prevent machine contamination, brush side. common causes of grooving include using the wrong brush grade, a brush with impurities, or contamination. Watch and listen for vibrations or noises which can occur at low speed. having a dirty commutator can cause a poor connection between the brushes. it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface. Inspection during slowdown and until the machine stops. Of course, even with diligent cleaning and inspection, the time will eventually come when your carbon brushes need to be replaced.

from www.phynyxind.com

Clean dust and impurities in time to prevent machine contamination, brush side. Of course, even with diligent cleaning and inspection, the time will eventually come when your carbon brushes need to be replaced. Watch and listen for vibrations or noises which can occur at low speed. clean the motor regularly: it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface. common causes of grooving include using the wrong brush grade, a brush with impurities, or contamination. having a dirty commutator can cause a poor connection between the brushes. Inspection during slowdown and until the machine stops.

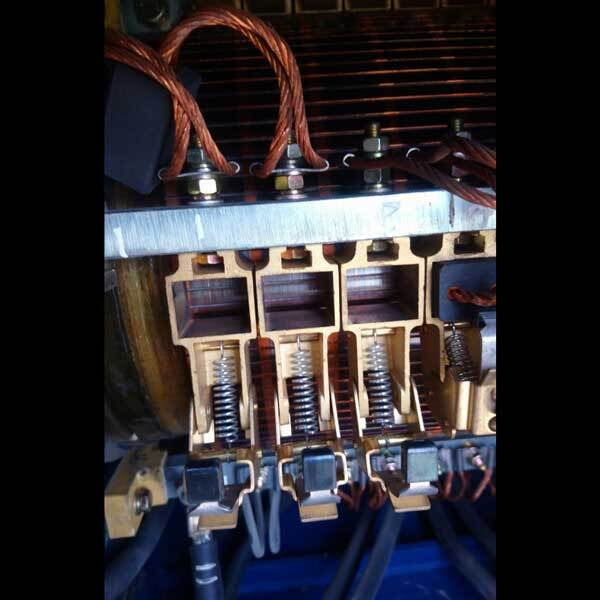

CLEANING CARBON BRUSH HOLDERS Phynyx Industrial Products Pvt. Ltd.

How To Clean Carbon Brushes Of course, even with diligent cleaning and inspection, the time will eventually come when your carbon brushes need to be replaced. Watch and listen for vibrations or noises which can occur at low speed. it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface. clean the motor regularly: Inspection during slowdown and until the machine stops. having a dirty commutator can cause a poor connection between the brushes. common causes of grooving include using the wrong brush grade, a brush with impurities, or contamination. Clean dust and impurities in time to prevent machine contamination, brush side. Of course, even with diligent cleaning and inspection, the time will eventually come when your carbon brushes need to be replaced.

From www.youtube.com

Teardown and Inspection of Bosch washing machine Motor Rotor Carbon How To Clean Carbon Brushes it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface. clean the motor regularly: Inspection during slowdown and until the machine stops. Of course, even with diligent cleaning and inspection, the time will eventually come when your carbon brushes need to be replaced. Clean dust and impurities. How To Clean Carbon Brushes.

From gmbbodyforum.com

How to Clean Carbon Out of Exhaust A Detailed Guide Air Intake How To Clean Carbon Brushes Of course, even with diligent cleaning and inspection, the time will eventually come when your carbon brushes need to be replaced. Inspection during slowdown and until the machine stops. Watch and listen for vibrations or noises which can occur at low speed. clean the motor regularly: Clean dust and impurities in time to prevent machine contamination, brush side. . How To Clean Carbon Brushes.

From www.theartofdoingstuff.com

How to Replace Carbon Brushes On Any Motor. The Art of Doing Stuff How To Clean Carbon Brushes clean the motor regularly: Watch and listen for vibrations or noises which can occur at low speed. having a dirty commutator can cause a poor connection between the brushes. it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface. Clean dust and impurities in time to. How To Clean Carbon Brushes.

From www.theartofdoingstuff.com

How to Replace Carbon Brushes on any motor. The Art of Doing StuffThe How To Clean Carbon Brushes Inspection during slowdown and until the machine stops. common causes of grooving include using the wrong brush grade, a brush with impurities, or contamination. Clean dust and impurities in time to prevent machine contamination, brush side. Watch and listen for vibrations or noises which can occur at low speed. having a dirty commutator can cause a poor connection. How To Clean Carbon Brushes.

From www.youtube.com

How to Change Carbon Brushes in a Washing Machine YouTube How To Clean Carbon Brushes common causes of grooving include using the wrong brush grade, a brush with impurities, or contamination. Inspection during slowdown and until the machine stops. it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface. having a dirty commutator can cause a poor connection between the brushes.. How To Clean Carbon Brushes.

From www.youtube.com

EVEO 4 in 1 Record Cleaning Kit plus Vinyl Cleaning Carbon Brush YouTube How To Clean Carbon Brushes clean the motor regularly: Of course, even with diligent cleaning and inspection, the time will eventually come when your carbon brushes need to be replaced. it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface. Clean dust and impurities in time to prevent machine contamination, brush side.. How To Clean Carbon Brushes.

From civilseek.com

7 Tips to Maintain Your Carbon Brushes How To Clean Carbon Brushes having a dirty commutator can cause a poor connection between the brushes. Of course, even with diligent cleaning and inspection, the time will eventually come when your carbon brushes need to be replaced. Watch and listen for vibrations or noises which can occur at low speed. it's recommended to gently clean the brush surfaces using a soft cloth. How To Clean Carbon Brushes.

From www.build-review.com

Power Tool Maintenance 5 Signs Your Carbon Brushes Need Replacement How To Clean Carbon Brushes Clean dust and impurities in time to prevent machine contamination, brush side. having a dirty commutator can cause a poor connection between the brushes. it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface. common causes of grooving include using the wrong brush grade, a brush. How To Clean Carbon Brushes.

From www.topdealsonline.shop

How Do You Make Carbon Brushes? 6 Step Guide Top Deals Online How To Clean Carbon Brushes it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface. having a dirty commutator can cause a poor connection between the brushes. common causes of grooving include using the wrong brush grade, a brush with impurities, or contamination. Inspection during slowdown and until the machine stops.. How To Clean Carbon Brushes.

From exorltuem.blob.core.windows.net

How To Clean Carbon Buildup On Throttle Body at Victor Santamaria blog How To Clean Carbon Brushes having a dirty commutator can cause a poor connection between the brushes. clean the motor regularly: Inspection during slowdown and until the machine stops. Clean dust and impurities in time to prevent machine contamination, brush side. it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface.. How To Clean Carbon Brushes.

From www.phynyxind.com

CLEANING CARBON BRUSH HOLDERS Phynyx Industrial Products Pvt. Ltd. How To Clean Carbon Brushes clean the motor regularly: Watch and listen for vibrations or noises which can occur at low speed. it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface. Of course, even with diligent cleaning and inspection, the time will eventually come when your carbon brushes need to be. How To Clean Carbon Brushes.

From www.youtube.com

How to Install a Carbon Brush YouTube How To Clean Carbon Brushes having a dirty commutator can cause a poor connection between the brushes. common causes of grooving include using the wrong brush grade, a brush with impurities, or contamination. Inspection during slowdown and until the machine stops. Clean dust and impurities in time to prevent machine contamination, brush side. it's recommended to gently clean the brush surfaces using. How To Clean Carbon Brushes.

From repairinuae.com

How to Replace Carbon Brushes on a Siemens Washing Machine How To Clean Carbon Brushes Inspection during slowdown and until the machine stops. it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface. Clean dust and impurities in time to prevent machine contamination, brush side. Watch and listen for vibrations or noises which can occur at low speed. common causes of grooving. How To Clean Carbon Brushes.

From usefuldiyprojects.com

How To Replace WornOut Carbon Brushes Useful DIY Projects How To Clean Carbon Brushes Watch and listen for vibrations or noises which can occur at low speed. Inspection during slowdown and until the machine stops. Clean dust and impurities in time to prevent machine contamination, brush side. Of course, even with diligent cleaning and inspection, the time will eventually come when your carbon brushes need to be replaced. common causes of grooving include. How To Clean Carbon Brushes.

From www.youtube.com

How To Clean Carbon Off Your Engine! YouTube How To Clean Carbon Brushes it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface. Watch and listen for vibrations or noises which can occur at low speed. Of course, even with diligent cleaning and inspection, the time will eventually come when your carbon brushes need to be replaced. clean the motor. How To Clean Carbon Brushes.

From www.youtube.com

DIY Replace Carbon Brushes On An Impact Driver YouTube How To Clean Carbon Brushes Clean dust and impurities in time to prevent machine contamination, brush side. Inspection during slowdown and until the machine stops. having a dirty commutator can cause a poor connection between the brushes. it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface. Of course, even with diligent. How To Clean Carbon Brushes.

From www.theartofdoingstuff.com

How to Replace Carbon Brushes On Any Motor. The Art of Doing Stuff How To Clean Carbon Brushes common causes of grooving include using the wrong brush grade, a brush with impurities, or contamination. Of course, even with diligent cleaning and inspection, the time will eventually come when your carbon brushes need to be replaced. clean the motor regularly: Inspection during slowdown and until the machine stops. it's recommended to gently clean the brush surfaces. How To Clean Carbon Brushes.

From www.youtube.com

Sparking carbon brushes Cleaning the armature commutator bar repair on How To Clean Carbon Brushes common causes of grooving include using the wrong brush grade, a brush with impurities, or contamination. clean the motor regularly: it's recommended to gently clean the brush surfaces using a soft cloth and be careful not to damage the carbon surface. having a dirty commutator can cause a poor connection between the brushes. Of course, even. How To Clean Carbon Brushes.